Welding

& Fabrication

Enroll now! We’ll walk you through everything you need to know to become a student.

Apply Now

Get helpful updates on programs, deadlines, and other tips about enrolling.

Request Info

Come see why Southwestern Oregon Community College is a great place to learn.

Visit

CONTACT

Text or Call: 541-240-8227

Email

Take welding classes to launch your path to a hands-on technical career!

No prior experience needed. Pursue a two-year Assocociate’s degree or start with a one-year certificate in Welding & Fabrication.

Skip the office! Master processes like oxy-fuel cutting, plasma, MIG, TIG, and flux core. Whatever certificate or degree path you take, Southwestern’s training prepares you for a job as a welder, with career opportunities that span the globe.

A new group of welding students starts every Fall Term. Join us Fall 2026!

Enroll now! We’ll walk you through everything you need to know to become a student.

Apply Now

Get helpful updates on programs, deadlines, and other tips about enrolling.

Request Info

Come see why Southwestern Oregon Community College is a great place to learn.

Visit

CONTACT

Text or Call: 541-240-8227

Email

Need help with costs?

Ask about possible support through SNAP Training & Employment Program (STEP)

Scholarships Available!

Apply annually Jan. 1 – March 1 through the SWOCC Foundation

Degrees & Certificates

Specific overview and descriptions of welding classes you’ll take for each degree/certificate.

Welding & Fabrication

A new cohort of students starts each Fall! Pursue a two-year degree or start with a one-year certificate.

- Welding, Associate of Applied Science (AAS) – Two-year degree that provides training for entry-level employment and offers the technical knowledge necessary for career advancement. Prepare for manufacturing employment opportunities and develop basic pipe welding and fitting skills.

- Welding, Certificate of Completion – One-year certificate prepares students for entry-level jobs in metal working fields. Required courses are applicable toward the AAS Welding degree.

Welding Equipment

NOTE: Instructors will help you confirm the correct items during the first week of class, and there may be options for you to use financial aid to purchase your items!

Required Equipment

Purchase items individually, as needed, or purchase a “welding kit” through our industry partner, Industrial Source. The welding kit option may be purchased in-person at Industrial Source, or via the Campus Store–this is a good option for students wanting to charge the equipment to their financial aid.

PPE

- Welding Hood shades 9-13

- Extra cover lens

- Leather sleeves or jacket (no cotton jackets)

- Gauntlet welding gloves:

- Stick

- MiG

- Tig

- All leather boots – NO SYNTHETIC PARTS (recommend safety toe)

- Clear safety glasses

- Heat shield for back of gloves

- Cotton welder cap

- Ear plugs

- Clear face shield

- Shade 5 face shield (no glasses)

- Knee pads

- Respirator (rated for welding and grinding)

TOOLS

Reminder: plastic tools melt!

- 4 1/2” grinder (8 amp or higher)

- Combination square

- Tape measure

- Chipping hammer

- Wire Brush

- File

- Striker

- Tip cleaners

- Paint pen

- Soap stone

- Pliers or quick release clamps

- Sliding T bevel

- Bevel protractor

- Center punch

- 2’ framing square

- Torpedo level

- Calculator

- Drafting kit

- Compass

- Protractor

- Flat ruler

- Pencil

- Drafting triangle or 30-60-90 triangle

- Graph paper 1/4″ squares

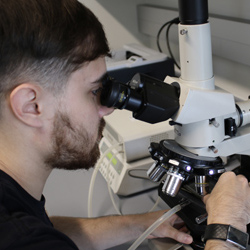

SKIP THE OFFICE

Master processes like oxy-fuel cutting, plasma, MIG, TIG and flux core

Welding employment opportunities span the globe

21.6% projected increase in welding job openings from 2020-2030

MEET OUR STUDENTS

“The welding program at SWOCC changed how I see life. The instructors genuinely cared about my success and taught me the value of slowing down and honing my skills. What I learned continues to shape my daily life and has helped me grow beyond the classroom.”

–Samantha Fry, Welding Graduate

JOB INFO

22 Annual Job Openings in the Southwest Region; 677 in Oregon

$48,780 is the 2021 Median Annual Wage in the Southwest Region; $39,374 is the Staring Wage; $62,670 for Experienced Welders

$50,382 is the Median Annual Wage in Oregon; $38,272 is the Staring Wage; $65,665 for Experienced Welders

Source: Oregon Employment Department

MEET YOUR INSTRUCTOR

Chelsea Clemens was born and raised in Coos Bay, and headed into high school with a mind toward being in the medical field, maybe a doctor. She took anatomy and physiology at Southwestern and soon enrolled at Portland State. It wasn’t long, though, before she came back home.

“I realized that was not my career choice. I didn’t like the city. I liked the more rural, slower pace. I like working with my hands.” She lined up a summer job at Roseburg Forest Products and was making good money. All the while, the crew she worked with kept teasing her that she’d be a good welder.

“I saw Southwestern had a welding program. I thought, ‘you know what? I’m going to take a few classes,” she said.

Soon Chelsea had a two-year welding degree and then a new job at the barge-building company Southern Oregon Marine. Still, she had an urge to teach, that started with class assistant experience at Southwestern and even younger, while in 4-H.

In 2015, Chelsea picked up a call from Southwestern’s former welding instructor. He kept in touch with his former teaching assistant, and was retiring. He thought she should apply. You know the story … eight years later, Chelsea is a welding instructor inspiring tomorrow’s boat builders, construction workers and metal fabricators.